Avritha

An Energy Efficiency Solutions For Manufacturing Industries

Step 1:

Machine-Level Energy Intelligence

Meter and monitor energy consumption at the machine level to gain real-time visibility into how and where energy is used across the factory floor, enabling accurate measurement and informed decision-making.

Step 2:

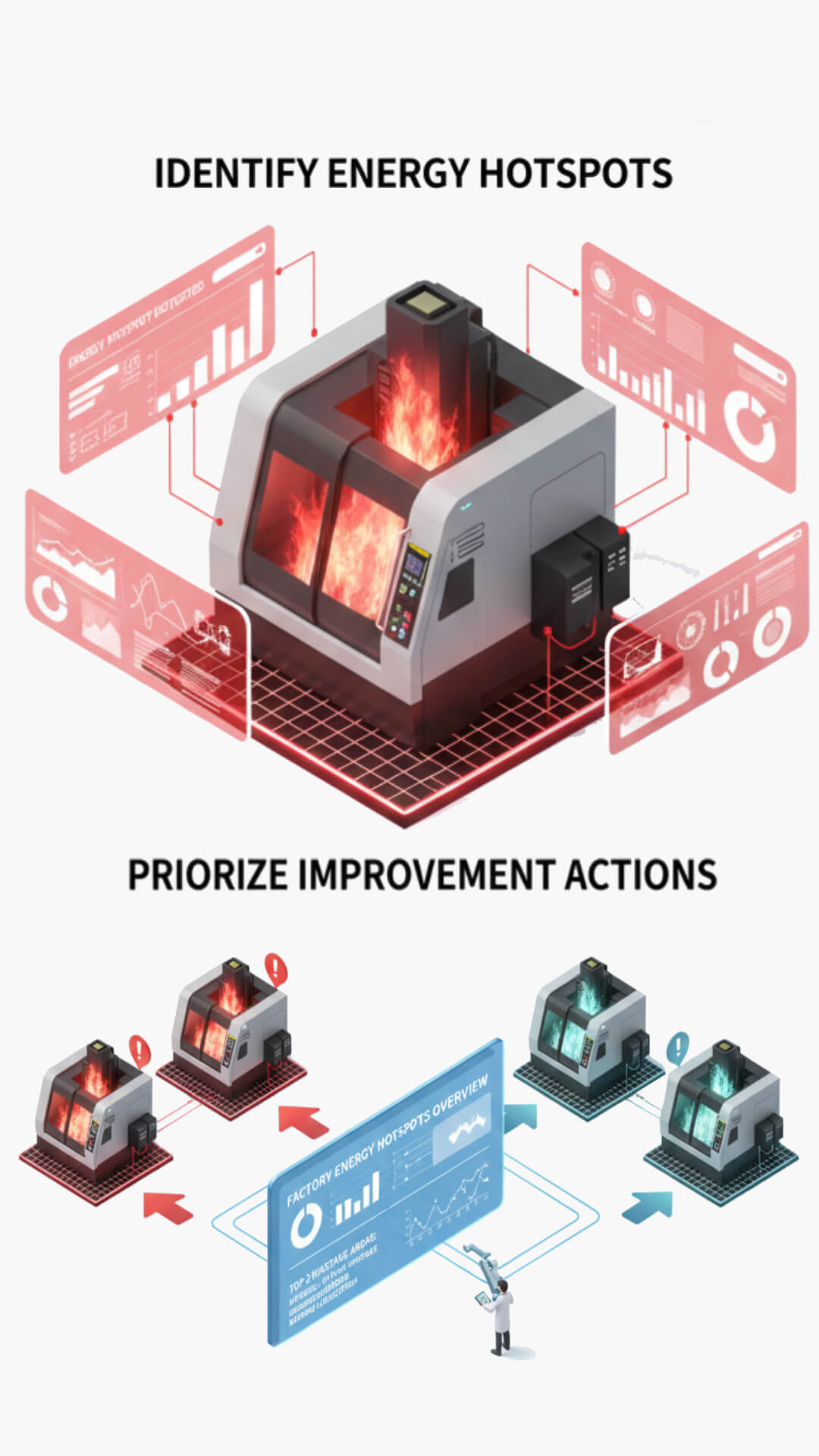

Identify Energy Hotspots

Analyze energy data to identify high-consumption zones and power wastage areas. This helps prioritize improvement actions, focus investments where they matter most, and eliminate hidden inefficiencies.

Step 4:

Commit to Sustainable Manufacturing Goals

Leverage actionable insights, performance tracking, and renewable integration to achieve long-term sustainability goals, reduce carbon footprint, and align operations with ESG and regulatory expectations.

Step 3:

Shift to Renewable Energy Sources

Replace or supplement high-energy-consuming units with renewable power sources such as solar or wind, reducing dependency on fossil fuels and supporting cleaner, more sustainable operations.

What benefits does Avritha bring?

Measurable Value Across Cost, Carbon, and Compliance

Avritha enables industries to reduce energy costs, improve operational efficiency, cut CO₂ emissions, meet ISO 50001 requirements, and build long-term sustainable and resilient operations.

Reduced Energy Costs

Avritha helps industries identify inefficiencies and eliminate energy waste, directly lowering energy consumption and reducing operating expenses.

Improved Operational Efficiency

By monitoring energy at machine and process levels, Avritha enables better equipment utilization, optimized operations, and consistent performance across plants.

Measurable CO₂ Emission Reduction

Avritha converts energy data into carbon insights, helping organizations track, manage, and reduce emissions in line with sustainability and decarbonization goals.

ISO 50001 Alignment and Compliance

Avritha supports structured energy management practices aligned with ISO 50001, simplifying compliance, audits, and continuous improvement initiatives.

Data-Driven Leadership Decisionsn

CXOs gain a single, reliable view of energy performance, enabling confident decision-making backed by real-time data and measurable outcomes.

Long-Term Sustainability and Business Resilience

By combining energy intelligence with renewable integration and continuous monitoring, Avritha helps industries build future-ready, sustainable, and resilient operations.